Meeting customer requirements for each and every customer over again, requires the ability to fully comprehend the task at hand. One of our principles is to look outside the box and to not just see our product as a stand-alone element, but as a part of a total paper output process. In this process we cater to the requests and requirements of our customers and create customized mail logistics concepts. continue»

Besides many standard systems, several customized facilities and individually developed mail logistics solutions have been installed for our customer base. Be it extensive modifications of standard components, mail car handling systems or box elevators in connection with ceiling-mounted conveyors – the possibilities are virtually endless. Below some examples of projects we have realized:

Example configurations

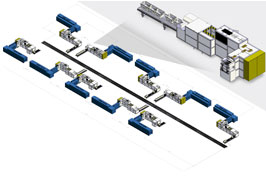

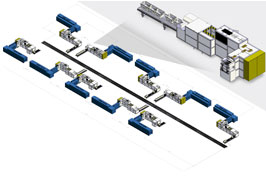

Example 1:

Equipping an entire hall with Post-Box-Systems. Variable operating screens for an optimal workflow. Realization in several partial stages: Start in 2009. Label concept: Press-in label.

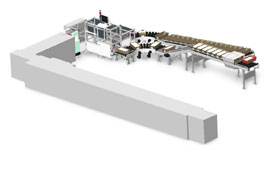

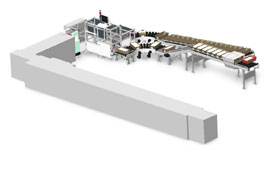

Example 2:

Modification of a Post-Box-System (PBS) for processing box containers for the Australian Mail Services with the automatic supply of empty postboxes and the automatic removal of filled postboxes. Realized: 2007. Label concept: Drop label.

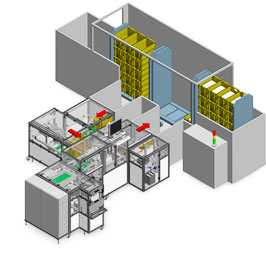

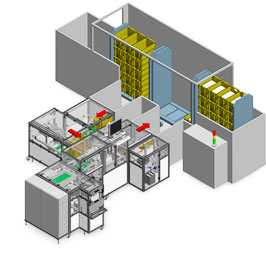

Example 3:

Post-Box-System (PBS) with a Wagon-Handling-System (WHS). Automatic unloading of empty postboxes (containers 1 and 2 of the Deutsche Post in this case) from a Deutsche Post AG trolley, supply of empty boxes to the Post-Box-System, filling, labeling and automatic removal of filled boxes to the Wagon-Handling-System (WHS). Finally the fully automatic stacking of the filled postboxes onto the wagon. Realized: 2010. Label concept: Insertion label.